Technology Overview

Sterilization is an essential requirement for the pharmaceutical, biotech and medical devices industries. Noxilizer has developed an ultra-low temperature nitrogen dioxide sterilization technology that addresses many of the challenges associated with traditional methods. NO2 is effective against a wide range of microorganisms. The primary mechanism of lethality is the degradation of DNA. Late outgrowth studies have no repair mechanisms for the DNA degradation.

Nitrogen dioxide is a true gas. The boiling point of NO2 is relatively low at 21°C, and Noxilizer employs sterilant concentrations that are well below the vapor pressure of NO2. The NO2 gas will not condense on devices. It is a surface sterilant. Therefore, NO₂ gas can sterilize prefilled syringes, while maintaining drug integrity, and medical devices with complex geometries.

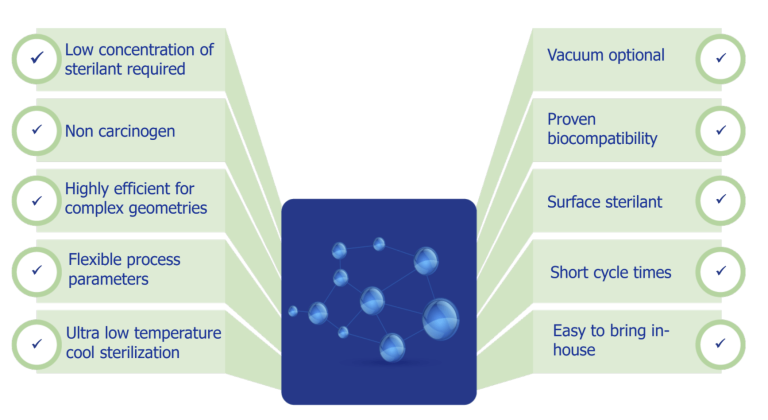

Only NO2 sterilization offers all the following benefits:

Nitrogen dioxide gas sterilization is ideal for sensitive biotech products and improves supply chain efficiency:

- Ultra-low temperature sterilization (10°C – 30°C) — maintains drug integrity

- Minimal vacuum option — prevents stopper movement

- Surface sterilization process — does not leach through the stopper

- Short cycle times (6-12 hours) including aeration

- Safe and easy to bring in house — reduces manufacturing time and cost

Aerates Rapidly – Minutes vs. Days

Low boiling point, coupled with the low NO2 sterilant concentrations, translates into rapid aeration of the sterilization chamber and exposed products.

NO2 does not permeate materials to the same degree as other methods, greatly reducing the overall cycle time of the sterilization process and eliminating the lengthy post-sterilization aeration. This benefit applies to terminal sterilization using a batch process or high level decontamination in isolators.

Residue Levels – Non-carcinogenic, non-cytotoxic and non-teratogenic

The rapid aeration process results in fewer residues on product and packaging. Noxilizer’s sterilant residues are non-carcinogenic, non-cytotoxic and non-teratogenic. Sterilized packages may be handled immediately after the cycle.

Flexible to Design Custom Cycles – Optimize Materials Compatibility and Sterilization

| Process Parameter | Range |

|---|---|

| NO2 Gas Concentration | From 1 mg/L to 20 mg/L |

| NO2 Exposure Time | Varies with application, typically less than 1 hour |

| Door-to-door Time | 6 to 12 Hours (for humidified cycle) |

| Relative Humidity | Typically 40% to 80% |

| Depth of Vacuum | 7 to 760 Torr |

| Chamber Temperature | 10°C – 30°C |

Compatible with Medical Device Materials

NO2 is less oxidative than traditional oxidizing sterilants like hydrogen peroxide and peracetic acid. Noxilizer has tested many medical device materials including metals, polymers, bioresorbables and adhesives. Compatible materials showed no increase in cytotoxic response. The true or ultra-low room temperature performance of the Noxilizer process allows temperature-sensitive materials to be processed.

| Compatible Materials | |||

|---|---|---|---|

| Stainless Steel | Polyethylene | Polyetherimide | Thermoplastic Elastomers |

| Aluminum | Polypropylene | Polycarbonate | |

| Gold (Plating) | PET/PETG | Cyclic Olefins | |

| Glass/Ceramic | Polystyrene | PVC* | |

| Fluoropolymers | Polysulfones | Silicone* | This list is not exhaustive |

| Viton (Gaskets) | PEEK/PAEK | Hypalon | |

*The specific type of material should be tested.

Compatible with Common Packaging

Noxilizer’s sterilization process is compatible with commonly used sterile barrier packaging. This includes: non-woven polypropylene, Tyvek® pouches, Tyvek®-Mylar® pouches and plastic tubs with Tyvek® lids. Noxilizer’s process is not compatible with cellulosic materials such as paper and cardboard.